This just had to be a treat. Preindustrial papermaking. In Bavagna, a village that seems to have reinvented itself as its own theme: ancient artisan village. Mercato delle Gaite is a Midieval Festival that takes place every weekend in June. It involves craft demonstrations. Of course, the crafters hope to survive another year, if not share a little prosperity. I was excited when Ken O'Connell told me about this particular field trip. But the stars had to align properly for it to be for certain. The cartier had promised to give us a complete tour of the paper mill and we had a time to be there.

Another bus ride and a promising adventure ahead. As usual, I wish I knew then what I know now. Bavagna has lots to offer and is thought by some to be one of the sweetest towns in the region. We were seeing only a tiny slice of it, but that promised to be exciting.

Most of us have made crude paper at one time or another, either from beating up old scraps of paper to gathering cotton dryer lint, and then pouring the pulp on on a screen, agitating the screen to spread the slurry, and either letting the water drip away or pressing it. Paper.

I had a job before I met Linny as the Pulperman on a large felt mill—felt being coarse paper for building materials. I drew from several sources of recycled and raw fibres to fill a giant blender and turn it all into consistent pulp to feed the paper making machine. Fibres are us. Then I worked as the Winderman, taking up the felt on rolls after it was dried and properly calendered (smoothed and sized) while passing through a series of drying rollers heated by steam. And I'd seen small batches of pulp made for special projects. I'd never seen an old paper-making hammer mill in real life.

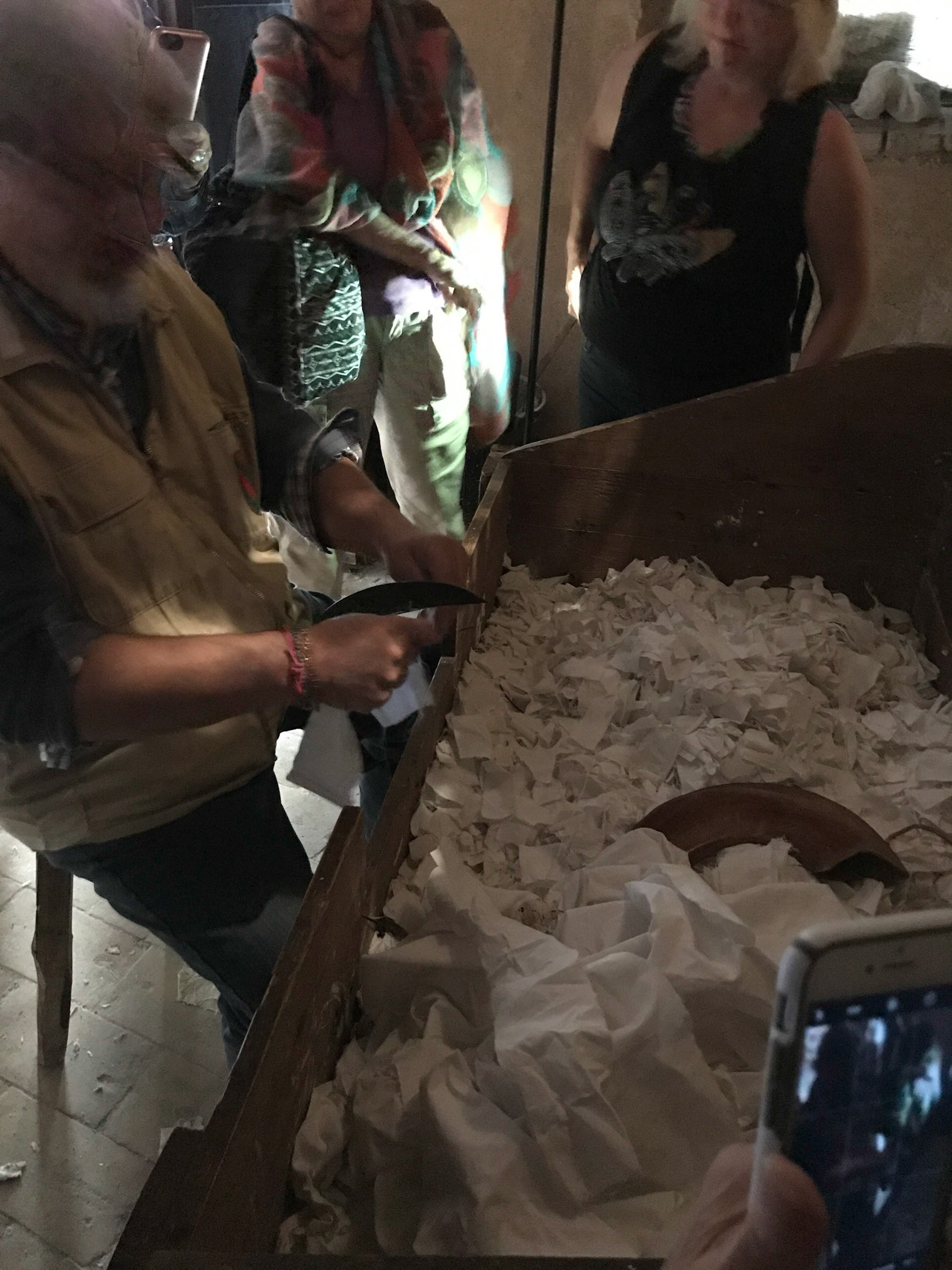

It took a bit of wandering for us to find the right narrow lane and follow it to the shop. It was close and dark inside except for the bright day shining starkly through the doors and a few small windows. Most of our class crowded in. The old beams of the ceiling yielded up no light. Gobbling it, instead. The surfaces were flocked with stray fibres. Tools of the trade lay within reach. The cycle here was relatively short, but the impact of the machine was profound then and remains so now. First, though, we were shown how the rags were cut on an open blade to make them manageable by the water-driven mill, made of strong woods that gain strength wet but cannot be allowed, now, to dry.

The barrel of pulp was stirred and screens were dipped. The art of knowing that the consistency of the pulp is right and the weight of the filled screen is right, and the pressure of the press is right and the angle of the sun is right. It was a wonderful presentation.

His artisan world is far larger than just the papermill. Glass is made in the kilns outside, just as it had been. Another skill returned. There's a settlement farmyard with pens of fowls, plus fowls on the loose.

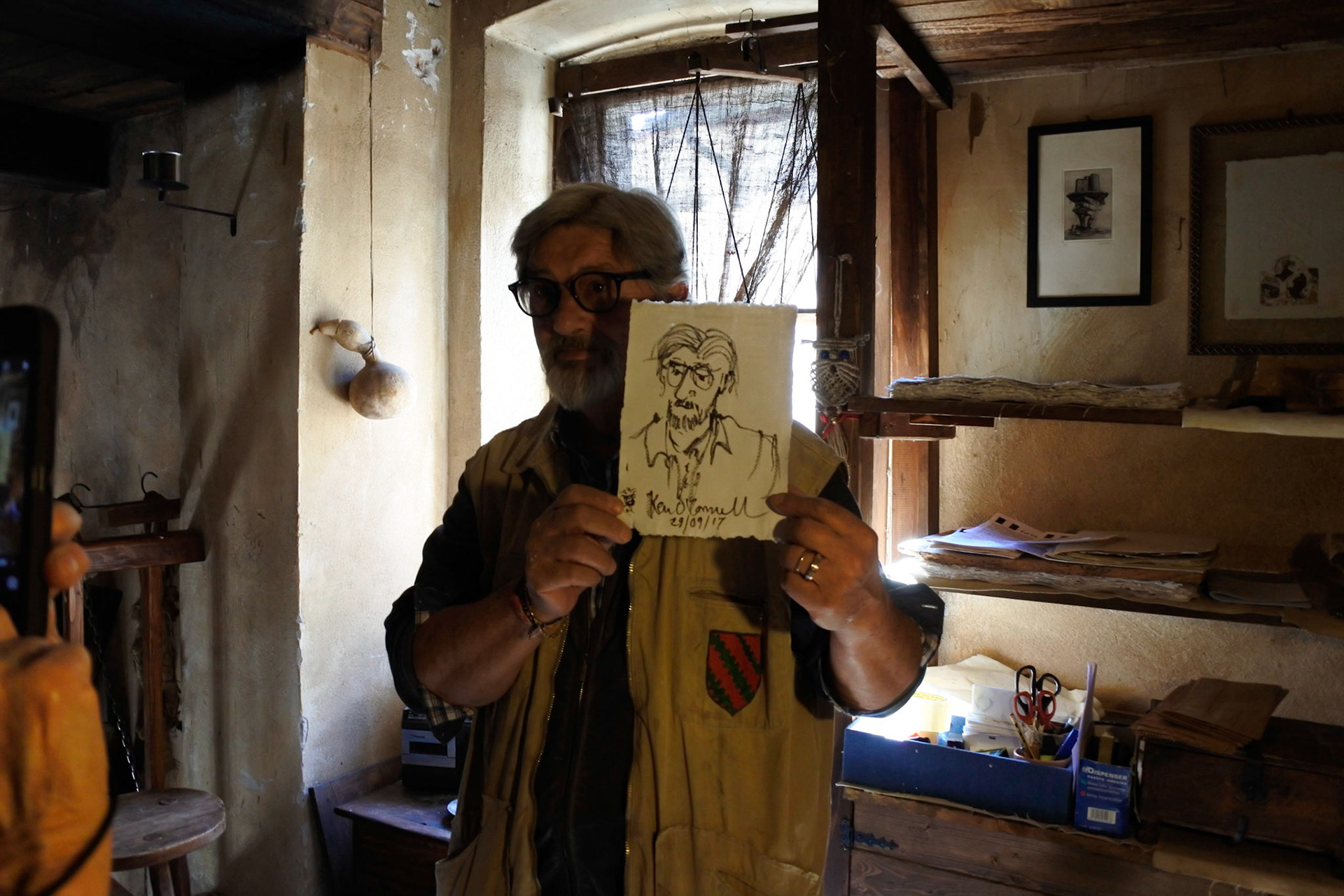

Then we hurried to find toilets and espresso or a snack and look for our bus. Ken handed me a piece of the master's paper. "To show your students," he said.